normalised thickness of positive tone photoresist was measured|Influence of material and process parameters in the dry : agent The resist was spin coated onto a 3 × 3 cm 2 silicon (1 0 0) substrate and the thickness was measured after a complete NIL thermal cycle (see Fig. 1) by ellipsometry . 21 de fev. de 2022 · A RPC é uma emissora de Curitiba que transmite programação variada, como notícias, esportes e entretenimento. Saiba como acompanhar a RPC ao vivo pelo .

{plog:ftitle_list}

WEBSinônimos de eivada: contaminada, infectada, cheio, repleto, vivo, animado, vigoroso, viçoso, lindo, abundante, basto, acesse e veja mais Dicionário online de Português. .

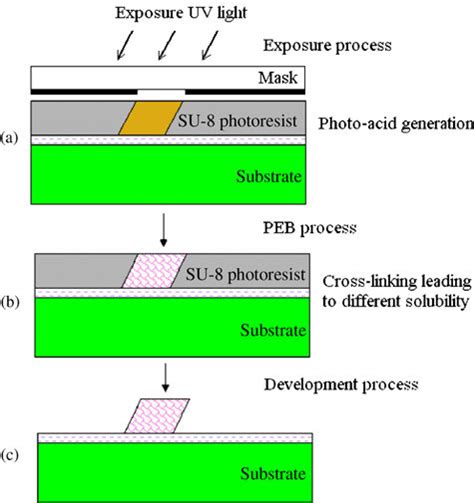

Thick Resist Lithography

1) The thickness of the positive-tone photoresist was measured after development as a function of exposure dose. Determine the contrast (y), Do, and D100.The graph below illustrates the mean photoresist thickness vs. spin speed for four (4) different photoresists (PR1, PR2, PR3, and PR4). Each photoresist has a different viscosity.Positive photoresists can be exposed by light in three spectral regions dictated by the emission of mercury lamps, the transmission of mask blanks, and the availability of suitable exposure .

Positive A values indicate the photoresist gets more transparent when exposed whereas a negative A indicates a photoresist that becomes more opaque with exposure.

Positive Photoresists

Photoresist Thickness Activity

The resist was spin coated onto a 3 × 3 cm 2 silicon (1 0 0) substrate and the thickness was measured after a complete NIL thermal cycle (see Fig. 1) by ellipsometry . Poly(phthalaldehyde) (pPHA) and copolymers with aliphatic aldehydes were investigated as dry-develop, positive-tone photoresist. Exposure of the films loaded with a . Positive-Tone Thick-Film Lithography Using DNQ-Novolac Resists and UV Exposure. In a positive-tone resist, the areas that are exposed to the radiation develop away .

The modeled photoresist has a contrast = 2.5, lower threshold D 1 = 4 mJ/cm 2, and upper threshold D 2 = 10 mJ/cm 2. The resulting cross section after development is normalized to .

The HN-018 photoresist was spin-coated on the glass and silicon wafer: step 1: 500 rpm for 5 s, step 2: 1000 rpm for 65 s for 8 μm thickness; step 1: 500 rpm for 5 s, step 2: 2000 .For stable lift-off processes in the μm and sub-μm range, we recommend the AZ® nLOF 2000 series for resist film thicknesses in the range 1-20 μm. This resist series is i-line sensitive and .limits of positive tone i-line photoresists David B. Miller, Adam M. Jones, Robert R. McLeod David B. Miller, Adam M. Jones, Robert R. McLeod, "Super-resolution critical . The resulting cross section after development is normalized to the initial film thickness, and has a width of 250 nm. . In th is paper, linewidth is measured at the base .

The photoresist film thickness range being used (i.e., generally divided into thin-film lithography and thick-film lithography) . Treatment of the resist with a developing solvent then leads to either removal of the exposed resist in the case of positive-tone photoresists or removal of the unexposed resist in the case of negative-tone . Koch et al. [22] have realized the fabrication of trenches with feature widths of about 1 μm in a S1813 photoresist film with a thickness of 1.9 μm. However, compared with spatial resolutions of structures fabricated with negative photoresists by using TPML, that of the positive photoresist of S1813 is still too lower.

karl fischer volumetric titrator price distribute

Filmetrics offers several instruments that measure photoresist thickness and etch rate, both in single-spot and mapping configurations. +1 858-573-9300 (24 Hr. Mon-Fri . Moreover, since positive and negative photoresists can be used together .

minimize the coating defects. This far exceeded the target thickness of 65 microns. Photoresist thickness and uniformity were measured on a DekTak. Shin-Etsu SIPR® 7120M photoresist is a chemically amplified I-line photoresist. The thickness at 300 RPM is 100µm. It is important to note that the SIPR® 7120M is formulated with an elastomer .CA. Moreover, a positive-tone chemically amplified Krypton Fluoride (KrF) photoresist was prepared, and the photolithography performance of the photoresist was evaluat-ed using a KrF laser exposure system, the result showed that the resolution could reach the level of 0.25 μm. Keywords Cedrylmethacrylate(CA) .ChemicallyThe Shin-Etsu SIPR 7120-20 photoresist was co ated with a a target thickness of 100 µm using the process and equipment described in Table 2. Photoresist thickness and uniformity were measured on a Dektak V300 profilometer. Shin-Etsu SIPR 7120-20 photoresist is a TMAH developable, chemically amplified positive photoresist with high Vapor-Phase Infiltrated Organic–Inorganic Positive-Tone Hybrid Photoresist for Extreme UV Lithography. . exhibit poor intrinsic EUV sensitivity, resulting in a lower throughput. The resist thickness required for EUVL is also lower (less than ≈30 nm) compared to the previous lithography technologies since the high-resolution patterns .

The profile of PSPI photo-patterns could be adjusted, to some extent, by inclining and rotating the exposing light beam [19].Excimer laser etching, plasma etching or wet etching with a mask made of thermally reflowable photoresist could also control the taper angle [10, [20], [21], [22]].Focus changing of the exposing light beam is another pathway to adjust the taper .A real pattern recording of photoresists with PR3 composition was performed; an optimal sensitivity of 20 mJ/cm2 and resolution of 1 lm of positive tone photoresists with 1 lm thickness was achieved. Ó 2008 Wiley Periodicals, Inc. J Appl Polym Sci 109: INTRODUCTION Vinyl ether-maleic anhydride (VEMA) has advantages that can overcome the .

Our group has reported a novel chemically amplified positive-tone photoresist based on bis-phenol A structure for . speed of 4000 r.p.m. for 90 s to form uniform films with the thickness of approximately 77 nm. . and 60 000 × 60 000 dot @Vector scan (Crestec Corp.). Film thickness was measured by AST SE200BM spectroscopic ellipsometer. .was coated using a different casting spin speed. The tables list the photoresist thickness at nine (9) test points (TP) on each wafer and the spin speed (SS) of each wafer. The photoresist thickness was measured in Angstroms (Å). (1 µm = 10,000 Å) a. Plot a graph comparing the nine wafers mean photoresist thickness vs. spin speed. Be sure to .(positive) or unexposed (negative) regions, resu lting in transferring the desired pattern on it. For these, knowledge of the photoresist exact thickness is crucial for the calculation of the necessary radiation energy dose. Traditionally in photolithography practice, the thickness of photoresist films is deduced

Two thermal protocols were used to check an impact of the film thickness on the . At first a set-up that allows detecting the deprotection of 193nm positive tone photoresist will be presented to .

negative-tone photoresist Authors for correspondence: Shuangqing Wang e-mail: [email protected] . The sensitivity of positive-tone PMMA was reported to be about 350 µCcm−2 using 50 keV acceleration voltage [31]. In most cases, the sensitivity . Film thickness was measured by AST SE200BM spectroscopic ellipsometer. Scanning electron

The final exposure thickness measurement, for the dose of 196mJ cm −2, represents the totality of the deposited photoresist layer. The intersection between the trend line and the horizontal line added for this final exposure gives the dose for which the photoresist layer would have been completely penetrated (approximately 145 mJ cm −2 ).dose employed. The plot of normalized thickness of the resist film vs the EUV exposure dose is given in Figure 4. These studies showed that the normalized film thickness of PAS resist increases gradually with an increase in exposure dose, confirming our earlier conclusion that the PAS acts as a negative tone photoresist with TBAH developer .

Two novolak/diazonaphthoquinone (DNQ)-based positive tone photoresists designed for high film thickness, ma-P 100 and ma-P 1275 (Micro Resist Technology GmbH, Germany) with 30–70 μm layers, and the chemically amplified negative tone photoresist, NANO™SU-8 (MicroChem, Newton, MA, USA) with 100–1000 μm layers were chosen for the .this type of photoresist is called negative photoresist as shown in Fig. 1e, if areas where photoreaction occurs are more easily dissolved, unexposed areas would stay, and this type of photo-resist is de ned as positive photoresist as shown in Fig. 1f. Photoresists can serve as a protection layer to keep materials Evaluation of a novolak based positive tone photoresist as NanoImprint Lithography resist. Author links open overlay panel Alessandro . (Rohm and Haas). The resist was spin coated onto a 3 × 3 cm 2 silicon (1 0 0) substrate and the thickness was measured after a complete NIL thermal cycle (see Fig. 1) by ellipsometry (Rudolph Research The exposure dose where the line crosses the normalized film thickness of 1.0 is defined as the highest exposure dose at which 100% of the film remains after development, D 0. Resolution experiments were performed using a positive-tone Test Chart No. 1 purchased from Toppan Photomasks, Inc with feature sizes ranging from 0.4 to 45 μm.

A sample set composed of 15 to 70 μm-thick JSR THB151N negative tone UV photoresist layers [3] . include techniques where any uncertainty in the optical dispersion of the resists directly propagates into the thickness measurement. The key features of the assessed metrology tools are summarized in Table 1. A mesoscale computer simulation for positive tone chemically amplified resists is reported. The simulation is based upon detailed models of resist function, and the required simulation inputs are fundamental quantities that can be measured independently of lithographic performance. These input parameters include resist formulation variables such as polymer .

Photoresists are fundamental materials in photolithography and are crucial for precise patterning in microelectronic devices, MEMS, and nanostructures. This paper provides an in-depth review of recent advancements in positive photoresist research and development, focusing on discussion regarding the underlying mechanisms governing their behavior, . A positive-tone novolak photoresist (AZ6112; AZ-Electronic Materials) was used for this study. It was spin-coated onto a Si wafer using a spin coater (ACT-300A; Active) at 2000 rpm for 20 s and then prebaked at for 1 min on a hot plate (PMC 720 series; Dataplate). The photoresist film thickness was measured using a stylus-type surface-profile measurement .

Download Citation | Design and study of advanced photoresist materials: Positive tone photoresists with reduced environmental impact and materials for 157 nm lithography | Concern about using .THE BEST-SUITED PHOTORESIST The question of the optimal photoresist to use is at the beginning of each new photolithography process. In . Table 4 represents the attainable and processable fi lm thickness ranges of our AZ® and TI positive, nega-tive and image reversal resists. Whether and under which conditions or with which restrictions .

PROCEEDINGS OF SPIE

14 de set. de 2023 · + Milionária 77 acumula e prêmio pode chegar a R$ 73 milhões; veja dezenas. Da Redação. 14/09/2023 • 00:16. Topo. + Milionária: todos os sorteios .

normalised thickness of positive tone photoresist was measured|Influence of material and process parameters in the dry